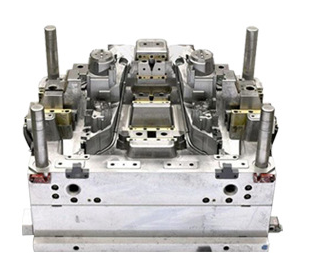

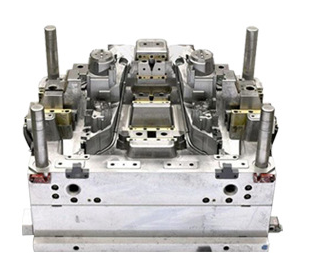

1. Car Mold products have become accustomed to life Car molds are products that we see every day, applied to various interior and exterior decorations of cars, such as plastic bumpers, shock absorbers, instrument panels, etc. So we cannot overlook any details during processing, so today we will talk about several points to pay attention to when processing automotive molds.

2. Several points to pay attention to when processing automotive molds

Automotive injection molds require higher processing equipment than traditional injection molds. There are generally two processing methods. The first step is to use a mirror surface spark machine for machining, just to ensure the high accuracy of the product. It is best to use graphite electrodes for electrical discharge machining, as the loss of graphite electrodes is much smaller than that of ordinary copper electrodes The second method we commonly use is electroforming. The use of electroforming technology can ensure that the mold has good accuracy. The only drawback is that the processing time is relatively long, and each cavity must be processed independently. Also, if there is slight damage during the production process, it cannot be repaired and only the damaged acupoints can be replaced. In terms of molds, mold temperature is also a very important parameter for automotive molds. Automobile mold processing is aimed at high-end consumers. Now we generally adopt the concept of high gloss Injection Molding, introducing rapid heating and cooling systems. Generally speaking, high mold temperature is very helpful for automotive parts molds, such as preventing difficulties in thin-walled filling and material shortage. However, excessive mold temperature can bring new problems, such as prolonged cycle time and shrinkage deformation after demolding. So it is very important to introduce a new mold temperature control system at this time. During the injection molding process, the mold temperature can be increased to allow the melt to fill the mold cavity faster, preventing the melt temperature from dropping too quickly during the filling process. The result is incomplete filling, and during demolding, the mold temperature can be quickly reduced to a temperature slightly lower than the plastic thermal deformation temperature, and then the mold can be opened and demolded.

Mr. ksj

Mr. ksj